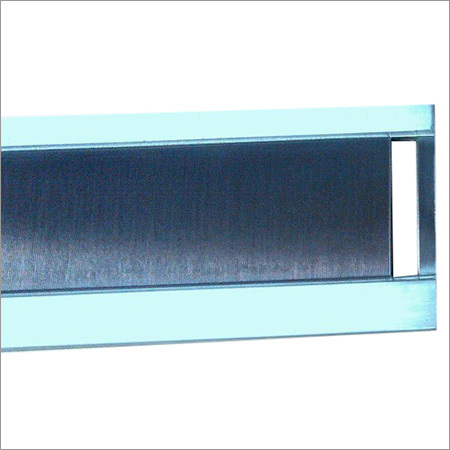

Rapier Reed

Rapier Reed Specification

- Tensile Strength

- 880-1200 N/mm

- Diameter

- Strip width customizable per weaving type

- Thread Type

- Suitable for all types of weaving threads (Cotton, Synthetic, Blended)

- Surface Finish

- Smooth, anti-rust, polished

- Noise Level

- Low

- Hardness

- 42-46 HRC

- Thermal Conductivity

- Medium (suitable for textile machine operations)

- Mounting Type

- Direct mounting to rapier weaving machines

- Automation Grade

- Semi-Automatic/Manual

- Features

- Precision slitting, corrosion resistant, durable edges, easy fitting

- Size

- Customizable (Width and Length as per textile machine requirements)

- Capacity

- Designed for high-speed weaving

- Part Type

- Spare part/Component

- Product Type

- Rapier Reed

- Material

- High carbon steel strips / Stainless steel

- Textile Machine Type

- Rapier weaving machine

- Spare/Component Type

- Weaving component

- Usage

- For efficient weft insertion and yarn separation

- Speed

- Supports up to 800 RPM

- Dimension (L*W*H)

- Custom dimensions as per order

- Weight

- Lightweight, varies with size

Rapier Reed Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Ahmedabad

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

About Rapier Reed

Our sophisticated production unit is professionally managed by trained personnel in order to offer defect free range of Rapier Reed. This is easy to fit in different textile and weaving machines. The offered reed is widely used in power looms for producing the fine quality clothes. It is precisely manufactured under the stern surveillance of our deft professionals by making use of quality assured materials and cutting-edge technology. Additionally, we are offering this Rapier Reed at reasonable prices to our prestigious customers.

Features:

- Energy efficient

- Optimum functionality

- Easy to operate

Advanced Design for Longevity

Rapier Reed incorporates reinforced edge protection to extend lifespan and maintain consistent weaving performance under demanding conditions. Its precision slitting and corrosion-resistant finish ensure durability, while the specially shaped dents reduce yarn friction, minimizing thread damage and improving output quality.

Optimized for Efficient Fabric Production

From synthetic to silk and woolen textiles, this reed is engineered for optimal weft insertion and yarn separation. Customizable according to your looms hole requirements and dimensions, Rapier Reed streamlines production across leading brands of rapier weaving machines, promoting higher speeds and lower noise levels.

FAQs of Rapier Reed:

Q: How can I customize the Rapier Reed to fit my rapier loom?

A: You can customize both the width and length, strip diameter, number of holes, and thread type to match your specific weaving machines requirements. Laser marking is also available for easy identification.Q: What materials are used in the construction of Rapier Reed?

A: Rapier Reed is manufactured from high carbon steel strips or stainless steel, ensuring robust tensile strength (880-1200 N/mm) and a polished, corrosion-resistant surface for extended durability.Q: When should I consider replacing my Rapier Reed?

A: Replace your reed if you notice increased yarn friction, decreased weaving efficiency, visible edge wear, or changes in noise and performance. Edge protection and corrosion-resistant features prolong service life.Q: Where is Rapier Reed commonly used?

A: This component is primarily used in rapier weaving machines within textile mills and industries that manufacture synthetic, cotton, silk, and woolen fabrics.Q: What process is involved in mounting or fitting the Rapier Reed?

A: Rapier Reed features direct mounting compatibility with leading brands of rapier looms. Installation is straightforward, with packing options like shrink-wrapped or bubble-packed sturdy cartons ensuring safe transit.Q: How does Rapier Reed contribute to efficient weaving operations?

A: With specially shaped dents that reduce yarn friction, reinforced edges for durability, and compatibility with high-speed weaving up to 800 RPM, Rapier Reed ensures smoother yarn separation and consistent weft insertion, improving overall productivity and fabric quality.Q: What are the primary benefits of choosing Rapier Reed for textile production?

A: Rapier Reed provides long-term reliability, reduced maintenance costs, improved yarn protection, customizable options, and versatility for a range of fabric types. Its lightweight design and medium thermal conductivity make it suitable for modern textile operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rapier Reed Category

Rapier Sulzer Reed

Price Range 750.00 - 950.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Features : Precision Construction, Wear Resistant, Corrosion Resistant, Long Service Life

Textile Machine Type : Other, Rapier Loom, Sulzer Loom

Noise Level : Low

Surface Finish : Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry