Call: 08045802789

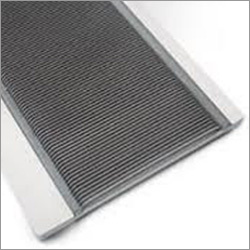

Velvet Making Reed

MOQ : 10 Pieces

Velvet Making Reed Specification

- Tensile Strength

- Excellent

- Diameter

- Standard/As per Machine Specifications

- Features

- Durable, Corrosion-Resistant, Precision Engineered

- Thermal Conductivity

- Good

- Hardness

- 58-62 HRC

- NO. Of Hole

- Multiple, Custom as required

- Size

- Customizable as per requirements

- Part Type

- Textile Machine Spare Part

- Surface Finish

- Polished

- Mounting Type

- Machine Mountable

- Capacity

- High Productivity

- Noise Level

- Low Noise

- Automation Grade

- Manual/Semi-Automatic

- Thread Type

- Uniform Warp-wise Threads

- Product Type

- Velvet Making Reed

- Material

- High-quality Stainless Steel & Brass

- Textile Machine Type

- Velvet Weaving Machine

- Spare/Component Type

- Reed

- Usage

- Used for making velvet fabric in looms

- Speed

- Suitable for High-Speed Operations

- Dimension (L*W*H)

- Customizable

- Weight

- Varies with size

Velvet Making Reed Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Ahmedabad

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Velvet Making Reed

Velvet Making Reed is designed keeping in mind the homogeneity of the dents. It is developed from optimum quality stainless steel with particular finishing ensuring excellent smoothness. With heavy-duty structure, it can easily withstand rust in stainless steel dent. The development of this reed is carried out in duraflex as well as soldering. Precise and even dent spacing ensures to provide ideal gradation of fabric.Precision-Engineered for Velvet Fabrics

Designed specifically for velvet and specialty textile production, our Velvet Making Reed guarantees accurate warp alignment and uniform weave quality. High-strength stainless steel and brass components deliver both durability and resistance to corrosion, making this reed ideal for demanding, high-speed weaving operations where consistency is paramount.

Customizable to Your Production Needs

Each reed is manufactured according to your precise requirements, with customizable blade thickness, dimensions, and hole specifications. Whether you need standard or specialized sizes, we provide fittings tailored to your velvet weaving machinery, enhancing both productivity and efficiency for manufacturers and exporters alike.

Long-lasting Performance and Easy Installation

With a highly polished surface and a hardness rating of 58-62 HRC, these reeds stand up to continuous use in industrial environments. The machine-mountable design allows for straightforward installation, while the robust packaging protects your investment during shipping and handling, ensuring every order arrives in optimal condition.

FAQs of Velvet Making Reed:

Q: How is the Velvet Making Reed installed onto a velvet weaving machine?

A: The Velvet Making Reed is machine-mountable and can be easily installed following your looms specific guidelines. Custom sizing ensures compatibility with a range of velvet weaving machines, facilitating quick adaptation and minimal downtime.Q: What customization options are available for blade thickness and hole shape?

A: Blade thickness can be specified from 0.06 mm to 0.10 mm, and hole shapes are typically rectangular, though custom configurations are available based on your precise textile requirements. The number and size of holes can also be tailored to your operational needs.Q: When should I replace the Velvet Making Reed in my textile machinery?

A: Replacement timing depends on production intensity and fabric quality requirements; however, if you notice decreased fabric quality, misalignment of threads, or increased noise, its advisable to inspect and replace the reed to maintain productivity and product quality.Q: Where are Velvet Making Reeds typically used?

A: These reeds are primarily utilized in velvet and specialty textile manufacturing units, particularly within looms designed for high-speed production of velvet fabric. They are used by manufacturers, exporters, and service providers handling textile machinery.Q: What steps are involved in the reed manufacturing process?

A: The process starts with high-grade stainless steel and brass selection, followed by precise machining, blade shaping, and drilling of holes as per specifications. The reed undergoes polishing for a smooth finish and is subjected to rigorous quality checks before being packed in a wooden box or carton for delivery.Q: What are the main benefits of using this Velvet Making Reed in textile production?

A: Benefits include enhanced durability, resistance to chemicals and corrosion, long service life, high productivity at elevated speeds, consistent cloth quality, and reduced operational noise. The precise engineering ensures stable performance even under continuous use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry