Call: 08045802789

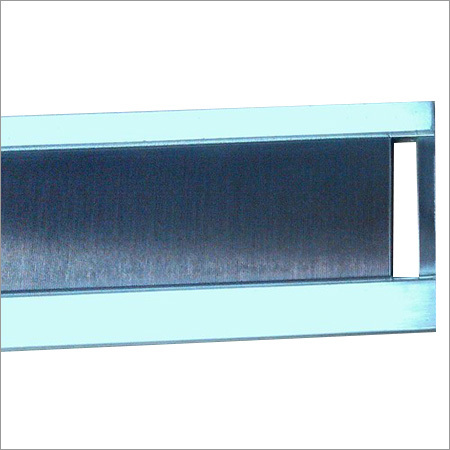

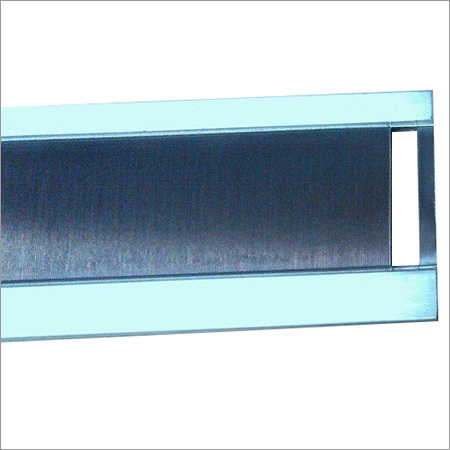

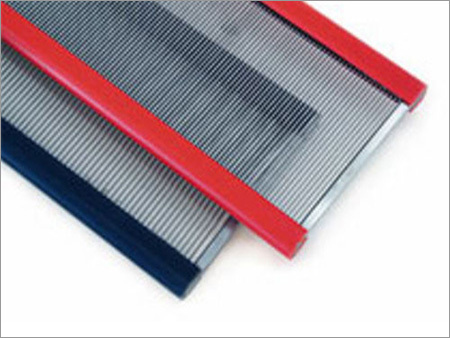

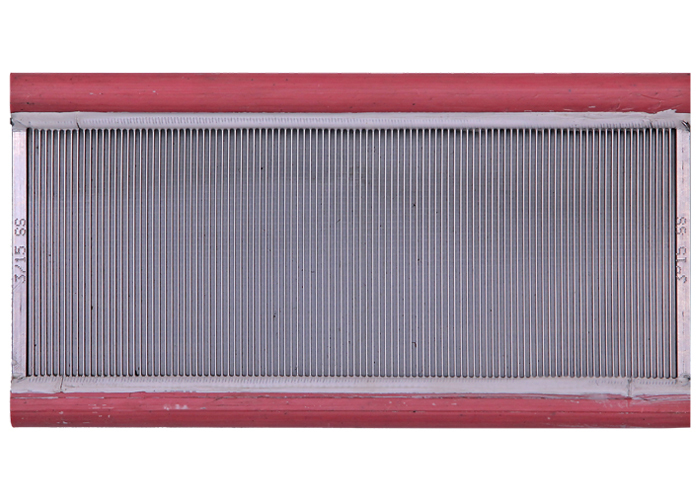

Steel Reeds

Price 150 INR/ Piece

MOQ : 10 Pieces

Steel Reeds Specification

- Surface Finish

- Polished

- Diameter

- Varies as per application Millimeter (mm)

- Capacity

- High precision weaving Kg

- Tensile Strength

- Above 710 MPa Megapascals (MPa )

- Thread Type

- Flat or Slotted

- Part Type

- Weaving Loom Part

- Mounting Type

- Slot Mount

- NO. Of Hole

- Custom as per specification (Dent per Inch)

- Features

- Corrosion resistant, Smooth edges, High durability

- Size

- Customizable as per requirement

- Thermal Conductivity

- Good Watt/Centimeter/C (W/(cm.C)

- Noise Level

- Low db

- Automation Grade

- Manual / Semi-Automatic / Automatic

- Product Type

- Steel Reeds

- Material

- High Carbon Steel

- Textile Machine Type

- Weaving Looms

- Spare/Component Type

- Loom Spare

- Usage

- For yarn separation in looms

- Speed

- Supports high-speed weaving RPM

- Dimension (L*W*H)

- As per requirement Millimeter (mm)

- Weight

- Lightweight to Medium depending on size Kilograms (kg)

- Custom Options

- Available as per client drawing/specification

- Color

- Natural Metal

- Dent Material

- Stainless Steel / Nickel Plated Steel

- Edge Type

- Beveled and Burr-free

- Application

- Textile Mill, Fabric Manufacturing

- Durability

- High, suitable for continuous operation

- Corrosion Resistance

- Excellent

- Finish Type

- Electro-polished

- Packaging

- Wooden Box or Custom Secure Packing

Steel Reeds Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 5 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Steel Reeds

Consistent innovation, coupled with an alert understanding of customers needs & demands, makes us the most well-known manufacturer and supplier of Steel Reed. This reed is highly acclaimed for its rust-proof, optimum strength and durable finish standard. Keeping in mind the diverse requirements of our valued customers, we provide the entire range in various sizes and at affordable price. This reed is designed with quality tested steel and the latest technology. We assure that our offered Steel Reed is outstanding on counts of durability and quality.

Superior Construction and Finish

Our steel reeds are crafted from high carbon steel, nickel plated, or stainless steel, ensuring outstanding strength for continuous textile operations. Electro-polished surfaces provide excellent corrosion resistance while beveled, burr-free edges help maintain fabric integrity and worker safety during high-speed weaving.

Custom Solutions for Every Need

We tailor steel reeds to client drawings and specifications, offering flexibility in dent count, dimensions, thread types, and mounting options. Each product facilitates high-precision weaving while accommodating fabric types and machine configurations used across textile mills and fabric manufacturing units.

Reliability and Durability

Engineered for longevity, steel reeds present low noise, lightweight-to-medium profiles, and high tensile strength (above 710 MPa), maintaining performance under demanding conditions. Secure packaging, including wooden boxes or custom options, ensures our reeds reach customers safely, wherever they operate in India or abroad.

FAQs of Steel Reeds:

Q: How are steel reeds used in textile mills and fabric manufacturing?

A: Steel reeds function as crucial weaving loom parts for yarn separation, guiding each thread evenly during the fabric weaving process. Their high precision and smooth edges facilitate consistent, quality fabric production in textile mills and fabric manufacturing settings.Q: What specifications can be customized for steel reeds?

A: We offer steel reeds with customizable size, dent per inch (number of holes), thread type (flat or slotted), mounting type, and dimensions. Clients may provide their own drawings or specifications to ensure the reeds fit their particular weaving looms and manufacturing requirements.Q: When should steel reeds be replaced in weaving looms?

A: Steel reeds should be replaced when signs of wear, corrosion, or bending appear, or if there are frequent yarn breakages and inconsistencies in fabric. Their durable construction supports continuous operation, but periodic inspection helps maintain optimal weaving performance.Q: Where can I purchase steel reeds and what are the packaging options?

A: Steel reeds are available through distributors, exporters, manufacturers, service providers, and suppliers across India. Packaging can be selected as sturdy wooden boxes or custom secure options, ensuring the reeds arrive intact and ready for installation.Q: What is the process for ordering custom steel reeds?

A: Clients can share their specific requirements or detailed drawings, including desired dimensions, dent count, material preferences, and finish types. The manufacturing team then collaborates to produce steel reeds tailored precisely to those needs, confirming details prior to production.Q: How does electro-polished finish benefit steel reeds in textile operations?

A: Electro-polished steel reeds offer superior corrosion resistance and a smooth surface, reducing thread abrasion during high-speed weaving and extending the accessorys lifespan. This finish is particularly beneficial in fabric manufacturing environments exposed to humidity or chemicals.Q: What are the main benefits of using these steel reeds in textile machinery?

A: The main advantages include high durability, precise yarn separation, low noise operation, excellent corrosion resistance, and the ability to support high-speed and automated weaving. Additionally, custom options and high hardness ensure compatibility and longevity in varied textile applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Metal Reed Category

Textile Metal Reed

Price 750.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial Textile Weaving

Product Type : Other, Textile Metal Reed

Dimension (L*W*H) : Customized Millimeter (mm)

Material : Other, Stainless Steel, Mild Steel

Metal Reed

Price 950 INR / Piece

Minimum Order Quantity : 10 Pieces

Usage : Industrial

Product Type : Textile Machinery Accessories

Dimension (L*W*H) : As per Requirement Centimeter (cm)

Material : Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry