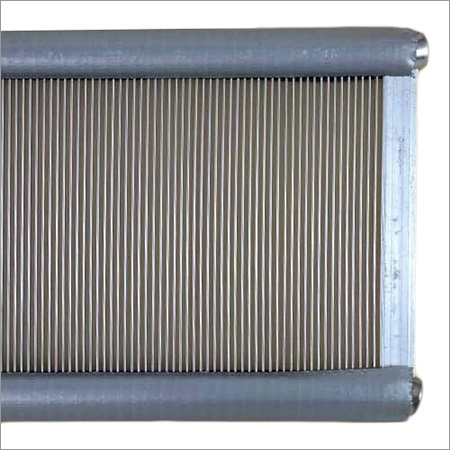

Steel Reed

MOQ : 10 Pieces

Steel Reed Specification

- Tensile Strength

- High tensile

- NO. Of Hole

- Multiple holes as per specification

- Features

- Corrosion-resistant, precise slots, long-lasting

- Capacity

- Heavy-duty

- Part Type

- Spare Part

- Surface Finish

- Polished

- Mounting Type

- Frame Mount

- Hardness

- HRC 45-55

- Thermal Conductivity

- Moderate

- Thread Type

- Plain/Reed wire

- Automation Grade

- Manual

- Noise Level

- Low

- Diameter

- Varies depending on design

- Size

- Custom sizes available as per machine requirement

- Product Type

- Steel Reed

- Material

- High-grade stainless steel

- Textile Machine Type

- Weaving Loom

- Spare/Component Type

- Replacement/Spare component

- Usage

- For yarn separation and alignment in loom

- Speed

- Supports high-speed weaving

- Dimension (L*W*H)

- According to requirement

- Weight

- Varies as per size

Steel Reed Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Ahmedabad

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Steel Reed

We have developed a large customer base in the national market by manufacturing and supplying superior quality Steel Reed. It is actually a part of a loom, and resembles a comb, this reed is available in different sizes as per the requirements of the customers within the promised time - frame. The offered reed is manufactured with the utmost precision by our adept professionals using supreme quality materials. Besides, these Steel Reed can be availed from us in several technical specifications at industry leading prices.

Features:

- Sturdy construction

- Unmatched performance

- Longer working life

Precision Engineering for Textile Weaving

Steel Reeds are crafted with precision-milled slots and custom dents per inch to ensure optimal yarn separation and alignment. By tailoring the slot width and reed density to match specific yarn types, these reeds maximize weaving efficiency and fabric quality. Their high-grade stainless steel construction ensures reliable performance in demanding textile environments.

Durable and Corrosion-Resistant Design

Utilizing cold-drawn and hardened high carbon stainless steel, Steel Reeds boast high tensile strength and a hardness rating of HRC 45-55. The polished finish and rust-resistant properties guarantee longevity even under heavy-duty, high-speed weaving conditions. The extended service life minimizes replacement frequency and operational downtime.

Fully Customizable for Diverse Textile Machines

Steel Reeds are available in a range of custom sizes and configurations, including blade thickness, thread type, and hole count. This versatility allows seamless integration with various weaving loom models and supports manual operation. Packaging options include plastic wrap and wooden boxes to safeguard reeds during distribution and storage.

FAQs of Steel Reed:

Q: How is the reed density determined for Steel Reeds in weaving applications?

A: Reed density, measured in dents per inch (DPI), is fully customizable to suit the specific fabric and yarn type being woven. Precise slot widths are engineered according to customer requirements, ensuring optimal yarn separation and weaving quality.Q: What are the advantages of using high carbon stainless steel and cold-drawn manufacturing for Steel Reeds?

A: High carbon stainless steel combined with cold-drawn and hardened processes provides superior tensile strength, corrosion resistance, and extended durability. This ensures the Steel Reeds can withstand abrasive and high-speed weaving environments while maintaining their performance.Q: When should Steel Reeds be replaced or serviced in a textile loom?

A: Steel Reeds should be checked periodically for signs of wear or deformation. Replacement is recommended when slots become uneven or abrasion compromises yarn alignment. Their robust construction gives them a long service life, minimizing the frequency of repairs.Q: Where are Steel Reeds typically installed within a weaving machine?

A: Steel Reeds are frame-mounted inside weaving looms, positioned to guide and separate yarns as part of the shedding and beating process. Their dimensions and configuration are customized to fit various machine models and operational requirements.Q: What is the process for ordering custom Steel Reeds to match my textile machinery?

A: To order custom Steel Reeds, provide your machines specifications such as desired DPI, slot width, blade thickness, and overall size. Manufacturers, distributors, and suppliers in India offer tailored reeds that meet international textile machine standards with various packaging options.Q: How do Steel Reeds contribute to the efficiency of textile weaving operations?

A: By offering precise yarn separation, corrosion resistance, and long-lasting durability, Steel Reeds enhance fabric quality, reduce downtime, and support high-speed, heavy-duty weaving. They operate with low noise and maintain performance even in demanding production environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry