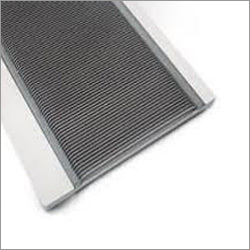

Velvet Reed

Velvet Reed Specification

- Thread Type

- Fine

- Diameter

- Custom as Required

- Thermal Conductivity

- Moderate

- Tensile Strength

- Robust

- Automation Grade

- Manual / Semi-Automatic

- Mounting Type

- Machine Mounted

- Surface Finish

- Smooth

- Hardness

- Medium

- Capacity

- High Precision

- Size

- Standard

- Features

- Superior Weaving, Fine Velvet Finish, Durable

- Part Type

- Weaving Machine Reed

- Noise Level

- Low

- Product Type

- Velvet Reed

- Material

- Velvet & Alloy

- Textile Machine Type

- Velvet Loom

- Spare/Component Type

- Loom Spare Part

- Usage

- Velvet Fabric Weaving

- Speed

- Supports High Speed Operation

- Dimension (L*W*H)

- Varies as Per Requirement

- Weight

- Light to Medium

- Customization

- Available

- Compatibility

- Fits all major Velvet Loom models

- Maintenance

- Low

- Packing Type

- Box / Customized

- NO. Of Hole

- Multiple (As Per Design)

- Manufacturing Technique

- Precision Engineered

- Durability

- Long Lasting

- Edge Type

- Protected / Rounded

- Color

- Silver / Custom

- Corrosion Resistance

- Yes

- Length

- Customizable

- Application

- Velvet Textile Production

Velvet Reed Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Ahmedabad

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Velvet Reed

Owing to the competency and knowledge of our professionals, we are manufacturing & supplying a wide gamut of Velvet Reed which application in narrow fabric looms, circular looms, label warping & sizing machines. These products are developed under the guidance of their skilled professional at par with set standards. Our offered Velvet Reed is available in different sizes to fulfill the broad needs of the customers. Our quality personnel inspect these reeds on different set industrial norms and can be availed by our renowned customers at market leading prices.

High strength Velvet Reed is available in maximum wearing out resistant design to ensure easy and swift movements of waft yarns. This is a durable range designed with excellent beat up resistant feature. This is available in the dent width range of 4 mm - 6 mm. It is designed from high grade stainless steel to provide maximum strength and sturdiness to the product.

Precision and Compatibility

Our Velvet Reed is crafted using precision engineering to ensure exact dimensions and reliable performance. It is designed to fit all major velvet loom models, offering flexibility and seamless integration for manufacturers. With customizable diameter and length, you can select the precise specifications required for your unique velvet weaving applications.

Superior Durability and Performance

The Velvet Reed boasts a smooth, corrosion-resistant surface made from high-quality velvet and alloy material. Its robust tensile strength and medium hardness contribute to long-lasting durability, while protected or rounded edges help maintain the integrity of velvet fabrics. Supporting high-speed operations, this component ensures consistent performance even with demanding textile production schedules.

FAQs of Velvet Reed:

Q: How does the Velvet Reed enhance velvet textile production?

A: The Velvet Reed is engineered for high-precision fabric weaving, offering a fine surface finish that preserves the quality and texture of velvet textiles. Its protected edges and smooth construction reduce fiber damage and ensure a superior velvet finish.Q: What customization options are available for the Velvet Reed?

A: We provide customized lengths, diameters, hole configurations, packing types, and colors. These options allow you to adapt the Velvet Reed to your specific loom model and production requirements, optimizing performance and output.Q: When is the Velvet Reed typically required during velvet fabric weaving?

A: This component is essential whenever replacing worn reeds or upgrading velvet loom setups for enhanced efficiency and surface quality. Its long-lasting durability means less frequent replacements, reducing downtime in manufacturing operations.Q: Where can the Velvet Reed be used in textile production?

A: The Velvet Reed is suitable for all velvet loom machines, supporting both manual and semi-automatic weaving. Its compatibility and adaptability make it ideal for use in textile mills, manufacturing plants, and workshops involved in velvet fabric production.Q: What is the process for installing a Velvet Reed?

A: The Velvet Reed is machine mounted and tailored to fit major velvet loom models. Installation involves securing the reed as per the looms specifications, ensuring proper alignment for effective weaving and minimizing machine noise.Q: How does corrosion resistance benefit Velvet Reed users?

A: Corrosion resistance ensures that the Velvet Reed maintains its integrity and performance over time, especially in humid or challenging manufacturing environments, leading to fewer replacements and improved cost-efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry